SERVICES

Subsurface Risk Report for Onshore Drilling Project

Project Overview:

- Location: West Texas, USA

- Project Type: Onshore Oil Drilling

- Objective: Drilling and completion of three horizontal wells targeting the Permian Basin.

Key Issues and Risks

1. High-Pressure Zones at Deep Depths (>1500m)

- Risk Level: Critical (8.0/10)

- Key Concerns:

- Blowouts: The risk of encountering high-pressure zones can lead to uncontrolled blowouts.

- Significant Formation Fluid Influx: Potential for large volumes of fluid to enter the wellbore unexpectedly.

MITIGATION MEASURES

- Seismic Surveys: Detailed seismic analysis to pre-identify high-pressure areas.

- Managed Pressure Drilling (MPD): Advanced pressure control techniques to manage wellbore pressures.

- Well Control: Installation and maintenance of Blowout Preventer (BOP) systems, along with crew training on emergency responses.

2. Wellbore Instability Across Depths

- Risk Level: High (6.0/10)

- Key Concerns:

- Faults and Fractures: Presence of geological faults and fractures may destabilize the wellbore.

- Differential Sticking: Risk of stuck pipes due to unstable wellbore conditions, particularly in shallow and mid-depth sections.

- Mitigation Measures:

- 3D Seismic Imaging: Use of 3D imaging to map out subsurface faults before drilling.

- Stabilization Techniques: Application of wellbore stabilization methods such as adjusting mud weight and utilizing rotary steerable systems (RSS).

3. Formation Damage and Poor Reservoir Quality (0-1500m)

- Risk Level: High to Medium (4.0-6.0/10)

- Key Concerns:

- Formation Damage: Potential damage to the formation during drilling, leading to reduced permeability and productivity.

- Low Permeability Reservoirs: Encountering reservoirs with low permeability, making hydrocarbon extraction less efficient.

- Mitigation Measures:

- Non-Damaging Fluids: Use of specialized drilling fluids designed to minimize formation damage.

- Hydraulic Fracturing: Preparation for hydraulic fracturing to enhance the flow of hydrocarbons in low-permeability zones.

4. Unexpected Formation Fluids (Mid-depth and Deep)

- Risk Level: High (6.0/10)

- Key Concerns:

- Water or Gas Influx: Encountering unexpected formation fluids can complicate drilling operations.

- Increased Costs: Unanticipated fluid influx can lead to delays and additional costs for control and management.

· Mitigation Measures:

*Logging-While-Drilling (LWD): Real-time monitoring tools to detect and react to fluid changes.

- Contingency Plans: Developing and rehearsing response plans to handle sudden fluid influxes efficiently.

Overall Risk Evaluation

- Average Risk Score Across Depths: 6.2/10

- Final Combined Subsurface Risk: Moderate to High (6.4/10)

Financial Impact and Mitigation Costs

- High-Pressure Zones:

- Estimated Cost: $2,500,000 for advanced pressure control systems and well control measures.

- Wellbore Instability:

- Estimated Cost: $1,200,000 for seismic imaging and wellbore stabilization techniques.

- Formation Damage and Reservoir Quality:

- Estimated Cost: $700,000 for non-damaging fluids and hydraulic fracturing preparation.

- Unexpected Formation Fluids:

- Estimated Cost: $500,000 for real-time monitoring tools and contingency planning.

- Total Estimated Financial Impact: $4,900,000

Conclusion and Recommendations

The drilling project faces several significant subsurface risks, primarily related to high-pressure zones at deeper depths, wellbore instability, and potential formation damage. However, with the outlined mitigation strategies and a comprehensive risk management plan, these risks can be effectively managed.

Key Recommendations:

- Prioritize Deep Depth Seismic Analysis: Focus on detailed seismic surveys at deeper depths to preemptively identify high-pressure zones.

- Enhance Wellbore Stability: Implement advanced stabilization techniques across all depth sections, particularly in fault-prone areas.

- Prepare for Unexpected Fluid Influx: Ensure LWD tools are in place and contingency plans are well-rehearsed to handle any unexpected fluid encounters.

By following these strategies, the project can mitigate major risks, minimize operational disruptions, and optimize drilling success.

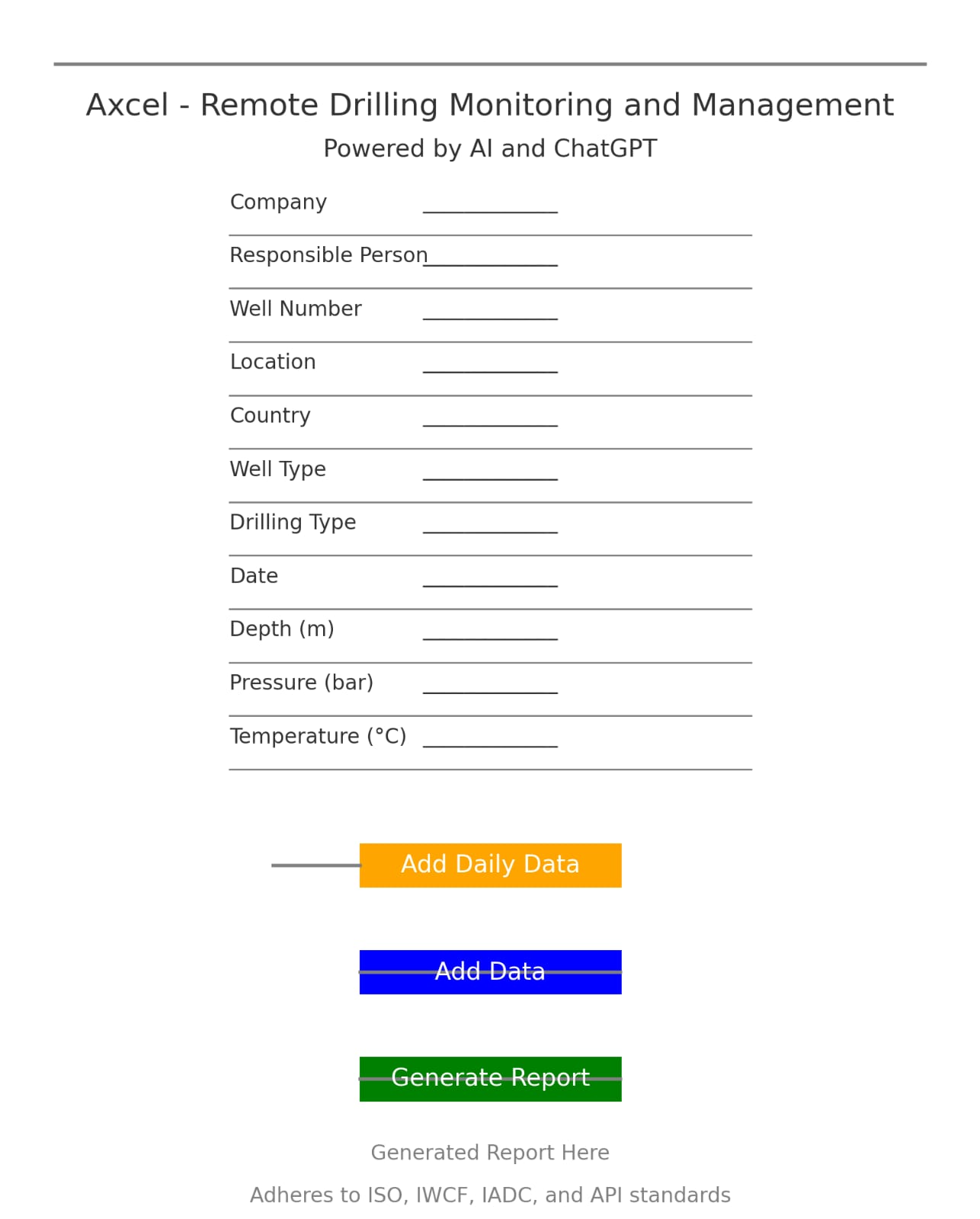

Our offer

Axcel's well drilling risk assessment services include:

1. Risk Analysis and Identification - Our team of drilling experts conducts a detailed analysis of the situation and identifies all risk factors that may affect well drilling.

2. Risk assessment - Identify each risk

Online Consultation

Assessment of customer needs and requirements

Establishing a personalized action plan

The offer of specific solutions and recommendations

Monitoring and reporting progress